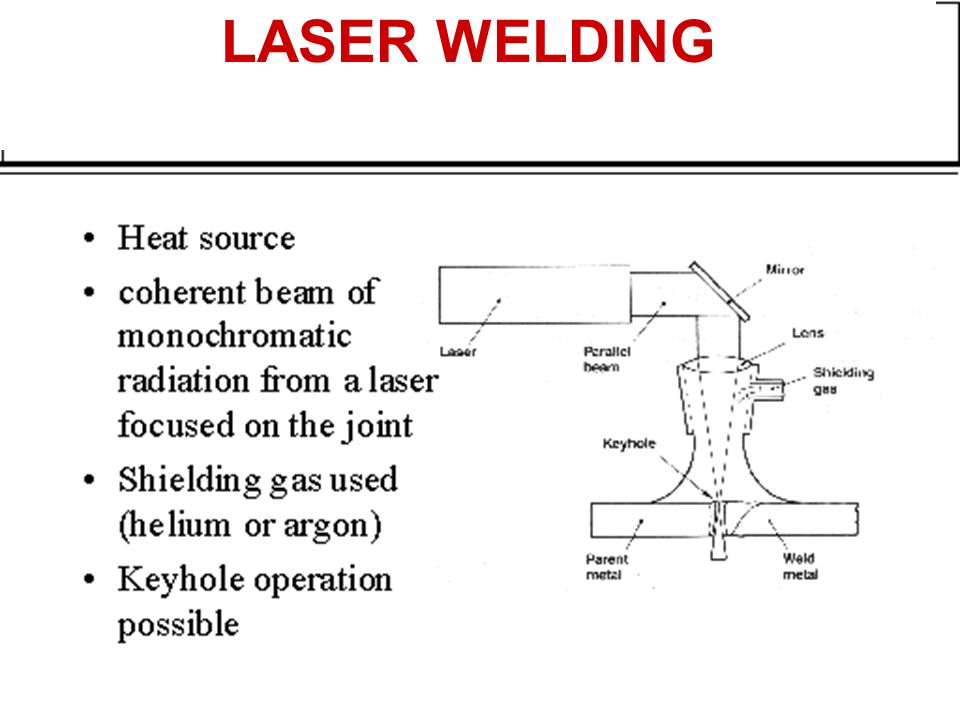

3 conduction mode welding where the heat is transferred from the surface into the material by thermal conduction 3 keyhole welding where the laser beam energy is transferred deep.

Laser beam welding process pdf.

Pdf laser welding is used in.

High productivity reduction of scrap and re work.

Laser welding process and three zones weldmaster.

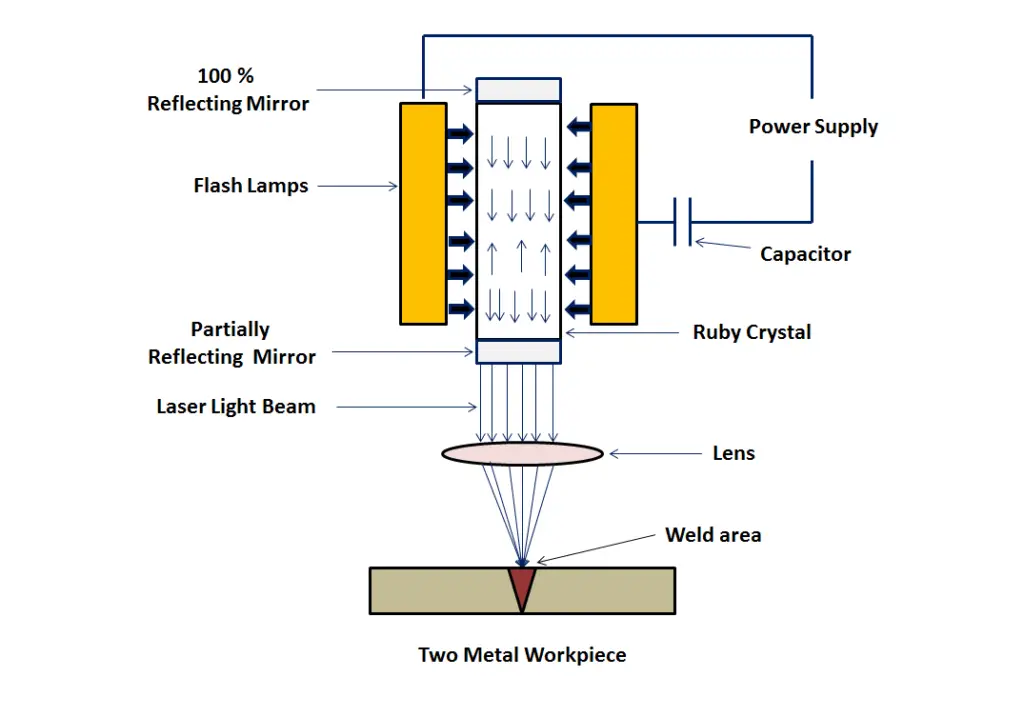

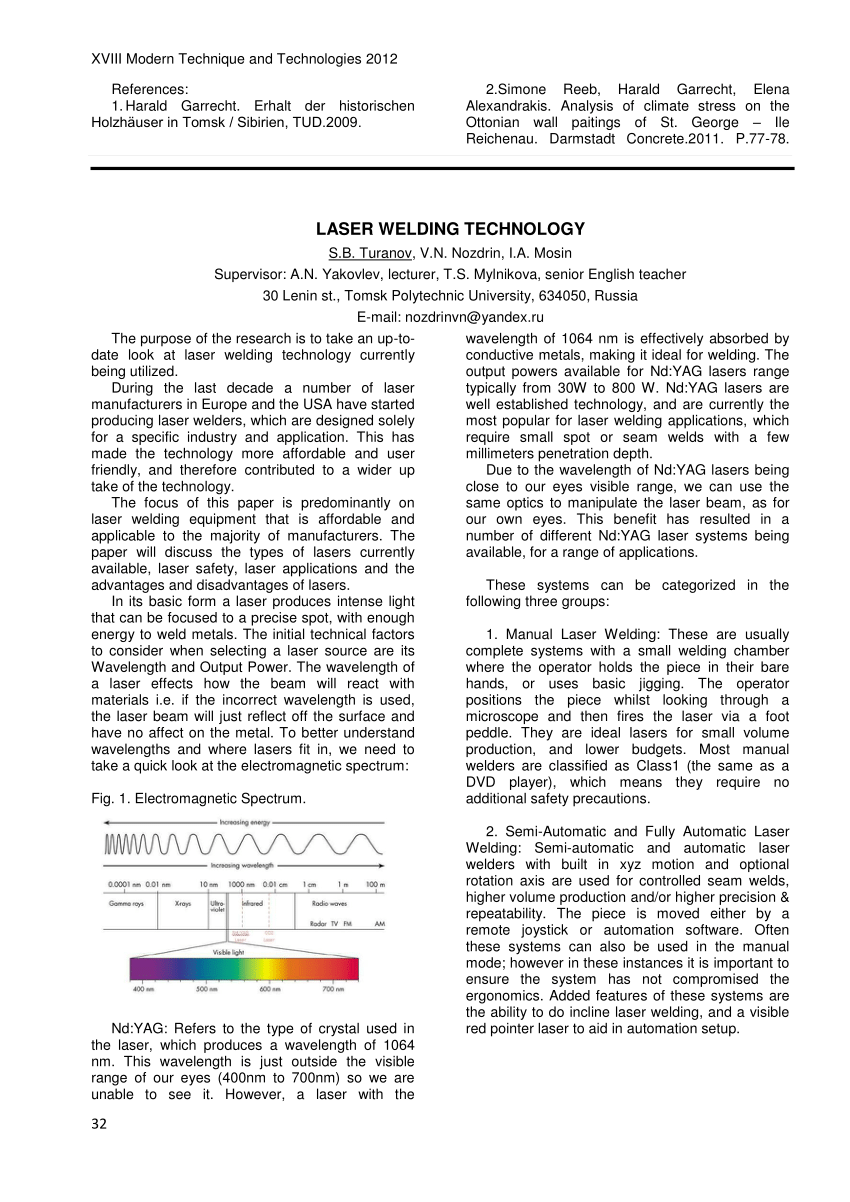

It utilizes an impurity in a host material as the active medium.

The laser beam heats and melts the edges of the workpiece forming a joint.

2015 page 2 of 14 three the improvement to process yield through the reduction of product scrap and field failures far outweighs the cost of validating the laser welding process.

Thus the neodymium ion nd is used as a dopant or purposely added impurity in either a glass or yag crystal and the 1 06 μm output wavelength is dictated by the neodymium ion.

Laser beam welding lbw is a welding process in which heat is generated by a high energy laser beam targeted on the workpiece.

Laser beam welding process diagram.

Description heating of the workpiece above the vaporization temperature and.

Laser beam welding is a fusion welding process in which two metal pieces are joined together by the use of laser.

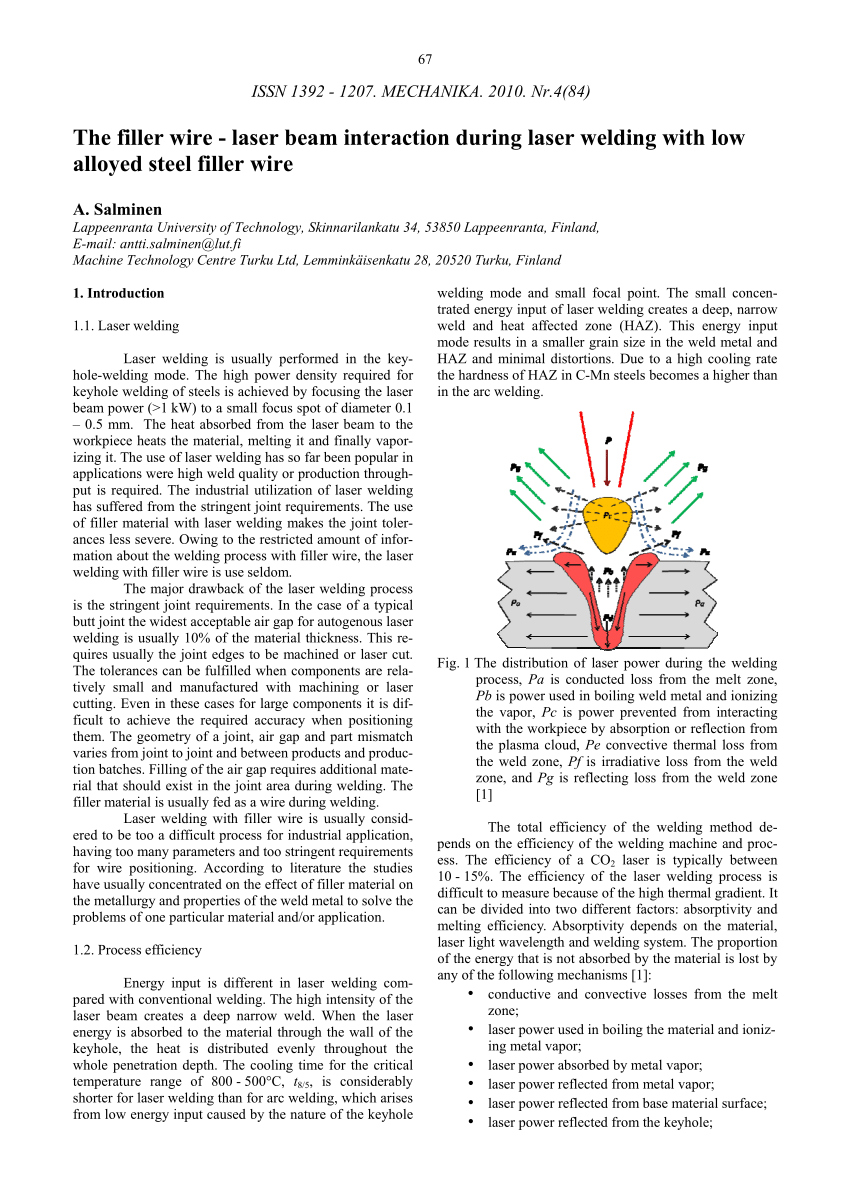

Laser beam processing gas welding seam work t piece s melt heat conduction welding.

The laser welding process 05 types of welding processes as shown in fig.

High power density weld process high laser uptime 98 cost savings.

4 there are two main methods of laser welding.

Validating the laser welding process a case study david w.

Laser welding claims the laser beam to focus greater energy in a space point melting and welding parts such as material creating a very stable and resistant junction between these.

The surface measurement beam is laterally offset at the processing level.

The laser beams have enough energy and when it strikes the metal pieces produce heat that melts the material from the two metal pieces and fills the cavity.

The energy of a narrow laser beam is highly concentrated at 10 8 10 10 w cm 2 so a weak weld pool is formed very rapidly for about 10 6 sec.

An axial direction to the welding beam.

Solana and negro 1997 em ployed both a top hat and a gaussian distrib ution for the laser beam.

The laser beams are focused to the cavity between the two metal pieces to be joined.